Overview of car engine parts names

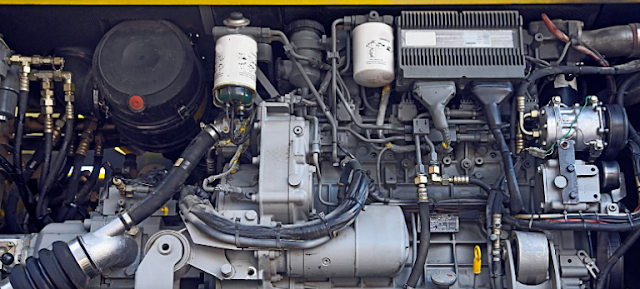

There are several automobile car engine parts names that work together to provide power for vehicles on the road. The primary purpose of a car engine is to create power from fuel in order to drive the vehicle. Several distinct pieces work together in the vehicle engine to accomplish this. Each component of a car’s engine is critical. These items must be in good functioning order to function properly.

Engines in automobiles are built around sealed, robust metal cylinders. The majority of modern automobiles have four to eight cylinders, while some can have as many as sixteen! The cylinders are designed to open and close at precisely the right times, bringing in fuel to join with the spark for internal combustion and releasing the exhaust gases created. While an engine has multiple components, we’ve collected a list of the most important automobile engine parts and their roles that power your vehicle. Refer to the diagram to see where they are located on your engine.

Different car engine parts names and Components and Their Functions:

The following are the various Engine Parts and their Functions:

- Piston

- Intake and Exhaust Valves

- Spark Plug

- Carburetor

- Connecting Rod

- Crank

- Crankshaft

- Manifold

- Intake Manifold

- Piston Rings

- Exhaust Manifold

- Piston pin

- Supercharger

- Poppet Valves

- Radiator

- Flywheel

- Engine Bearing

- Cylinder Head

- Push Rod

- Rocker Arm

- Catalyst Converter

- Fuel Injector

- Turbo Charger

- Fan

- Governor

- Sensor

- Water Pump

- Combustion Chamber

- Fuel Tank

List of car engine names of parts

Cylinder Block

The IC (Internal Combustion) engine’s major component is the cylinder block. It is the section of the engine where all of the engine’s operations take place, such as intake, suction, compression, combustion, exhaust, and so on. In IC engines, the cylinder’s job is to contain the fuel and guide the piston.

The cylinders are composed of cast iron and cast steel to withstand all of the temperature and pressure generated by the burning of fuel. As a result, the cylinder is constructed in such a way that its compressive strength is great. Because of the high pressure and temperature, it also need cooling in the engine cylinder.

Pistons

Pistons are cylindrical devices having a flat top surface. The piston’s job is to transport the energy released by combustion to the crankshaft, which then propels the vehicle. During each crankshaft rotation, pistons move up and down within the cylinder twice. Pistons in engines spinning at 1250 RPM will move up and down 2500 times per minute. Inside the piston are piston rings, which are designed to aid in compression and minimize friction caused by the cylinder’s continual rubbing.

Cylinder head

The heavy lifters of an automobile engine are the above components, but the cylinder head is considerably more accurate. Valve springs, valves, lifters, pushrods, rockers, and occasionally even camshafts are all found in the cylinder head.

The cylinder head also regulates intake and exhaust passageways, which enable intake air into the cylinders during the intake stroke and exhaust gases to be removed during the exhaust stroke.

The cylinder head is joined to the engine with cylinder head bolts, and the space between them is filled by a head gasket. Engine problems are frequently caused by blown head gaskets.

combustion Chamber

The cylinder walls, cylinder head, and piston head make up a combustion chamber. It is a location where real fuel combustion takes happen.

Crankshaft

Within the crankshaft journals, the crankshaft is positioned in the lowest half of the engine block (an area of the shaft that rests on the bearings). The connecting rod connects this well manufactured and balanced mechanism to the pistons. At engine speed, the crankshaft converts the pistons’ up and down motion into a reciprocal motion, similar to how a jack-in-the-box works.

Timing Belt/Chain

– In order for the engine to function correctly, the camshaft and crankshafts are synced to guarantee perfect timing. The camshaft and crankshaft pulleys are grasped by cogs on the belt, which is constructed of heavy-duty rubber. The chain loops around pulleys with teeth, similar to a bicycle chain.

Piston Rings:

The piston rings are responsible for establishing a seal between the cylinder and the piston. It aids in preventing the engine’s combustion gas from leaking and bypassing the piston, as well as reducing friction surrounding the piston. Cast iron and alloy cast iron are used to make piston rings.

Camshaft

The camshaft may be positioned within the engine block or in the cylinder heads, depending on the vehicle.

Many contemporary automobiles have these in the cylinder heads, also known as Dual Overhead Camshaft (DOHC) or Single Overhead Camshaft (SOHC), and they are supported by a series of oil-lubricated bearings.

The camshaft’s job is to govern the timing of valve opening and shutting and to convert the rotating motion from the crankshaft to an up and down motion to control the movement of the lifters, pushrods, rockers, and valves.

Valves for Engines

Engine valves are mechanical components used in engines to control the flow of air, fuel, and exhaust gas in the combustion chambers or cylinder head when the engine is running.

The valve action is straightforward: the cam pulls the valves down into the cylinder against the spring, opening the valve to allow gases to flow and then closing the valve under the power of the spring.

The pressure in the combustion chamber efficiently aids in sealing the valve shut.

Valve for intake and exhaust

Inlet and exhaust valves govern and regulate the charge (or air) that enters the engine for combustion and the exhaust gases that exit the cylinder, respectively.

They can be found on the cylinder head or the cylinder walls. They usually have a mushroom-like head.

Air and fuel mixture enter through the inlet valve in petrol engines, but only air enters through the intake valve in diesel engines. In both circumstances, the exhaust valve is used to release exhaust gases.

The intake manifold is connected to the intake valves, and the exhaust manifold is connected to the exhaust valves. The intake and exhaust manifolds have already been discussed.

Spark Plug

In spark ignition (SI) engines, a spark plug is a component that is used to ignite the fuel. Spark ignition engines are the most common engines that use gasoline as a fuel.

In SI engines, a spark plug produces a spark that initiates combustion. A battery or a magneto provide power to a spark plug.

Connection Rods

The connecting rod connects the piston to the crankshaft. It turns the piston’s linear motion into the crank’s rotating motion. The tiny end of the connecting rod is joined to the piston by a piston pin/gudgeon pin/wrist pin, while the big end is attached to the crankpin journal via bolts holding the upper and lower bearing covers. The bearing is made up of two half shells that are kept in position around the crank journal by the connecting rod’s large end.

The piston pin

A gudgeon pin is a kind of pin that links the connecting rod’s tiny end to the piston. Please refer to the preceding figure if you don’t grasp it.

Flywheel

The torque produced by the engine is not consistent and fluctuates. If a vehicle continues to operate with this variable power, it will cause significant pain to the rider as well as shorten the life of its various parts.

As a result, a flywheel is used to address the issue of fluctuating load. In most cases, a flywheel is attached to a camshaft. In a cycle of operation, it accumulates torque while its value is high and releases it when its value is low. It performs the function of a torque buffer.

Rocket Arm

The rocker arm translates the rotating motion of the cam or camshaft into a linear motion of the valve stem, which depresses the valve head, through a latch/tappet. The rocker arm oscillates or rocks around a fixed pivot rod (rocker shaft) in the cylinder head.

Crank:

Crank simply refers to the rotation or turning of the crankshaft of an engine. The crank functions as a spinning part that takes power from the connecting rod and delivers it to the crankshaft, acting as a lever between the connecting rod and crankshaft.

Liner for Cylinders

A cylinder liner is a thin metal cylinder-shaped component that fits into an engine block to make a cylinder. It is one of the most significant functional components of an engine’s interior.

The cylinder liner, which acts as the inner wall of the cylinder, provides a sliding surface for the piston rings while also holding the lubrication within.

The cylinder liner wears out due to the rubbing action of the piston rings and piston skirt during usage. This wear is reduced by the thin oil coating that coats the cylinder walls, as well as a layer of glaze that builds naturally as the engine is run in.

Related posts